Zeta-Mter

System |

(입자 전위차 측정기) |

|

|

|

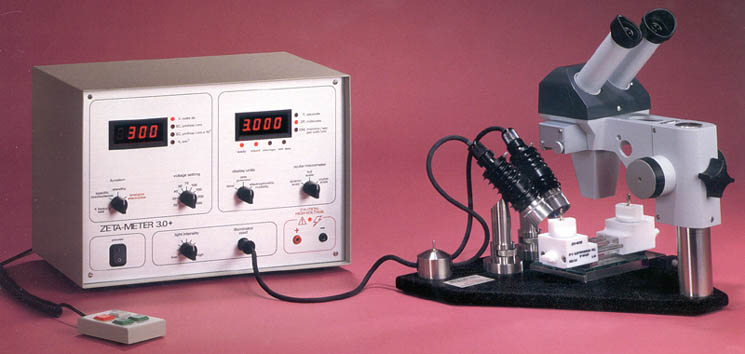

Model : Zeta-Meter System 3.0+ |

기본개념 |

Zeta Meter는 정전기적

전하의 영향을 측정하는 기계이다. 입자들은 서로 인접한

것끼리 척력을 작용한다. 한편 Van der waals force와 같은

인력도 작용한다.

콜로이드 용액에 기계적인 교반을 가했을때 충돌한

두 임자가 서로 인력을 작용한다면 둘은 뭉치게 되고 점점

더 자라나게 한다. 그러나 만약 서로 척력을 일으킨다면

그 정전기적 힘은 둘 사이의 거리가 짧아질수록 증가하므로

콜로이드 그 상태를 유지하게 된다.

미립자 표면의 전하는 그 콜로이드와 부유용액 간에

전위차(millivolt 단위의 크기로)를 일으키게 되는데 이것이

zeta potential이다. zeta potential은 두 전극 사이에

전압을 걸어주었을 때에 전극 사이에 존재하는 대전된 콜로이드가

움직이는 것을 이용하여 쉽게 측정할 수 있다. 그리고

그 이동속도는 zeta potential에 비례하게 된다. 이러한

현상을 electrophoresis(전기영동)라 한다. |

|

|

Zeta Potential |

-125 to +125

millivolts |

Electrophoretic

Mobility |

+20 to -20

microns/sec per volt/cm |

Specific

Conductance |

0 to 60,000

micromhos/cm, autoranging |

Temperature |

5 to 75℃ |

Concentration |

10 to 800,000

mg/l (0 to 80% solids by weight) |

Particle

Diameter |

1.5 to 100

microns (with standard 15x eyepieces)

0.4 to 10 microns (with optional 25x eyepieces) |

Sample Size |

20 ml minimum

(standard cell)

5 ml minimum (low volume cell) |

Suspending

Medium |

water or

otrganic liquids |

|

Applications |

Adhesives, Agricultural Chemical,

Asbestos, Atomic Energy

Beverages, biochemistry, Biomedicine

Coal, Dairy Product, Detergents, Dry Power Technology

Drystuffs, Emulsions, Fibers

Foods, Latex Production, Petrochemicals

Petroleum, Photographic Emulsions, Pigment |

Zeta-Potential 응용분야

1. Minerals &Ores (광물, 광석) - Coper, Lead, Zinc and Tungsten

2. Clays & Drillng Fluid - Paper, Adhesives

Ointments,

Rubber

and Synthetics

3. Ceramics : Slip Casting Control

4. Pharmaceuticals

5. Paints

6. Water and Wasterwater Coagulation

7. Paper Making

|

|

|

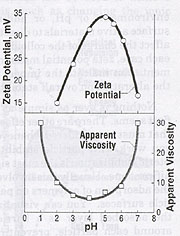

Control

of Slip Casting

Clay suspensions for slip casting must have their viscosity

minimized so that they pour readily and release trapped

air bubbles easily. The above figure shows the effect

of pH on the apparent viscosity and zeta potential of

thoria(ThO3). Note that a maximum zeta potential corresponds

to a low apparent viscosity. |

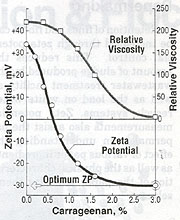

Fluidization

of an Antacid

Suspension

Fluidization is an alternative to flocculation. A negatively

charged colloidal polyelectrolyte is used as a

"fluidizing" agent. The polyelectrolyte adsorbs

onto the surfaces of insoluble particles and deflocculates

them once the zeta potential exceeds the critical value.This

graph illustrates the fluidization of an aluminum hydroxide

suspension using carrageenan sodium as the "fluidizing"

agent. The drops in zeta potential and viscosity of

the suspension correlate quite well with each other

and |

Zeta

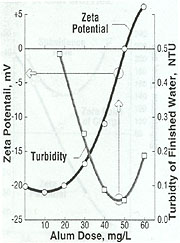

Potential Control of Alum Dose

There is no single zeta potential that will guarantee

good coagulation for every treatment plant. It will

usually be between 0 and - 10 mV but the target value

is best set by test, using pilot plant or actual operating

experience.

Once the target ZP is established, then these correlations

are no longer necessary, except for infrequent checks.

Just take a sample from the rapid mix basin and measure

the zeta potential. If the measured value is more negative

than the target ZP, then increase the coagulant dose

(andvice versa). |

|

are

produced by an increase in the concentration of carrageenan. |

In this example a zeta potential of

-3 mV corresponds to the lowest filtered water turbidity

and would be used as the target ZP. |

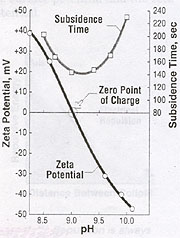

Determining Point of Zero Charge

These experiments with alpha-alumina show good correlation

between the point of zero charge as determined by zeta

potential and the point of maximum subsidence rate.

Subsidence rate is measure of the degree of coagulation. |

|

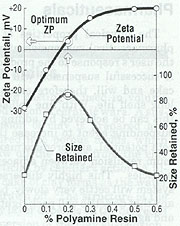

Synthetic Size Retention in Papermaking

The point of maximum size retention corresponds to a zeta potential of =4, which can be considered the optimum ZP. More positive or more negative values of the zeta potential cause a drop in the percent of size retained. Operating at the optimum value resultsin titanium oxide savings, improved sheet formation, increased wire life, improved sizing, pitch control, and biocide reduction. |

|

|

|