|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

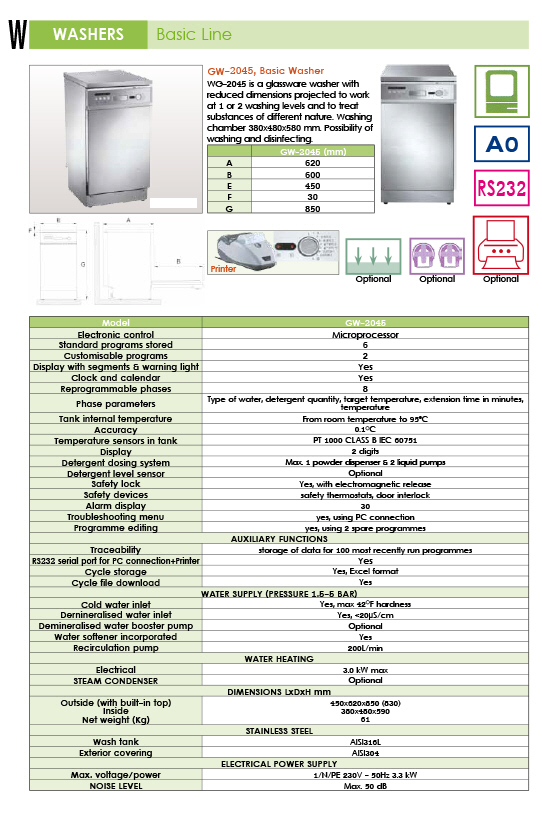

GW2045 operates on 1 or 2 levels and treats various types of glassware.

● Standard wash tank measuring 380x480x590mm

● Washing and disinfecting programs.

● Small size

|

CHARACTERISTICS

|

|

● Wash tank/door in AISI 316L acid-resistant chrome-nickel-molybdenum stainless steel

● External panels in AISI 304 stainless steel

● External dimensions: Ixdxh 450x600x850mm

● Useful tank dimensions: Ixdxh 380x480x590mm

● Two washing levels with rotating sprayer or injection trolleys

● Total washing area: 0.36m2

● Electronic programming

● 7 programs (plus one service program)

● Digital display

● Recirculation pump: 200L/min

● 1 dispenser for dosing alkaline powder detergent

● 1 peristaltic pump for acid liquid neutralizer

● 1 optional perstaltic pump for alkaline liquid detergent

● cold water connection ( 1 - 3.5 bar)

● Demineralized water connection

● Water consumption: 5L per phase

● Built-in water softner with automatic volumetric regeneration

● Monitoring of cycle in progress with remaining time shown on display

● Temperature control with temperature value displayed in real time

● Safety features: washing stops if door is opened, water level control, overheating safety, error messages displayed

● Water heating: electric

● Optional booster pump for non-pressurized demineralized wtaer

● Electric Power supply

- 1/N/PE 50Hz 230V 3.3kW

|

|

|

|

Accessories

|

| GW2045 Basic

Trolleys |

|

D-CS1

Upper standard basket with sprayer for

holding various glassware supports. Made of stainless steel. |

|

D-CS2

Lower standard basket for holding various

glassware supports. Made of stainless steel. |

| GW2045 Supports |

|

SB14

Support to hold Erlenmeyer flasks,beakers,

etc., to be used on the standard baskets D-CS1 and D-CS2. Capacity 14 items.

Recommended for Erlenmeyer flasks up to 1000ml. Takes up 1/2 of the D-CS1 and

D-CS2 baskets.

D-PF1

Complete bottom rack with central hole in 10x10mm

mesh. Takes up complete D-CS1 upper basket. |

|

SB9

Support for beakers of any size. To be used

on D-CS1 and D-CS2 standard baskets. Recommended for beakers less than 400ml.

Takes up 1/2 of the D-CS1 and D-CS2 basket.

D-PF2

Complete bottom rack in

10x10mm mesh. Takes up complete D-CS2 bottom basket. |

| GW2045 Injection

Systems |

|

LPM24

Injection washing support for both

pipettes and flasks with 12 positions for pipettes (up to 490mm in height) and

12 positions for narrow-necked glassware. |

|

LPM24+D-CS2

Injection washing support LPM24 to

be placed on the standard lower bsket D-CS2. |

|

LM24

Universal support for narrow-necked

glassware, flasks, round bottom flasks and measuring cylinders of various sizes.

Nozzles of four different sizes 24 positions. Takes glassware up to 490mm in

height. |

|

LM24+D-CS2

Injection washing support LM24 to be

placed on the standard lower basket D-CS2. |

|

|

|

|

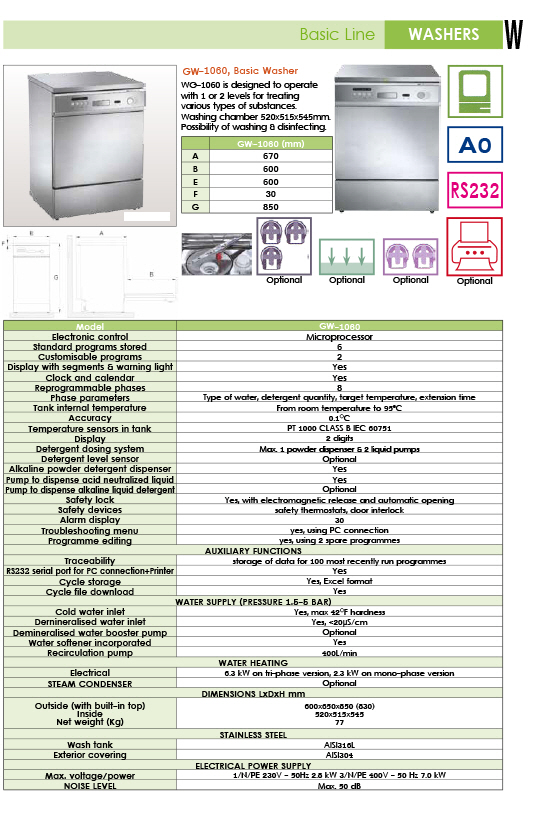

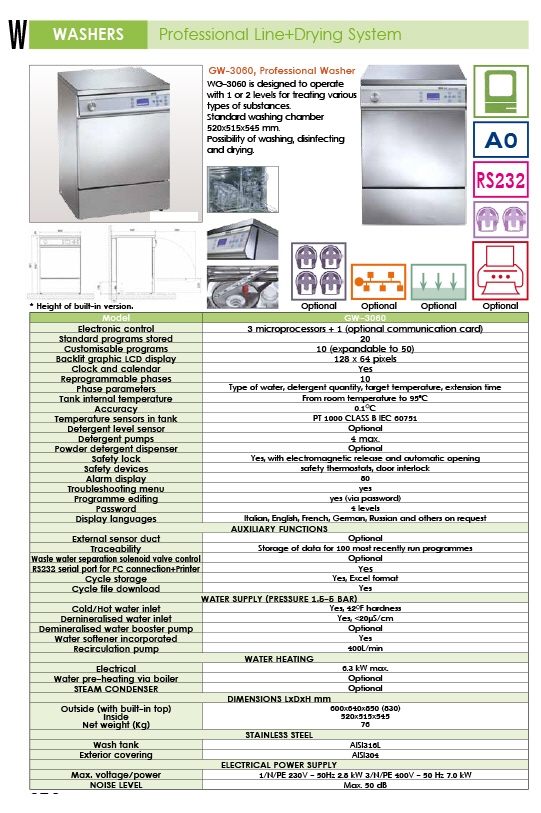

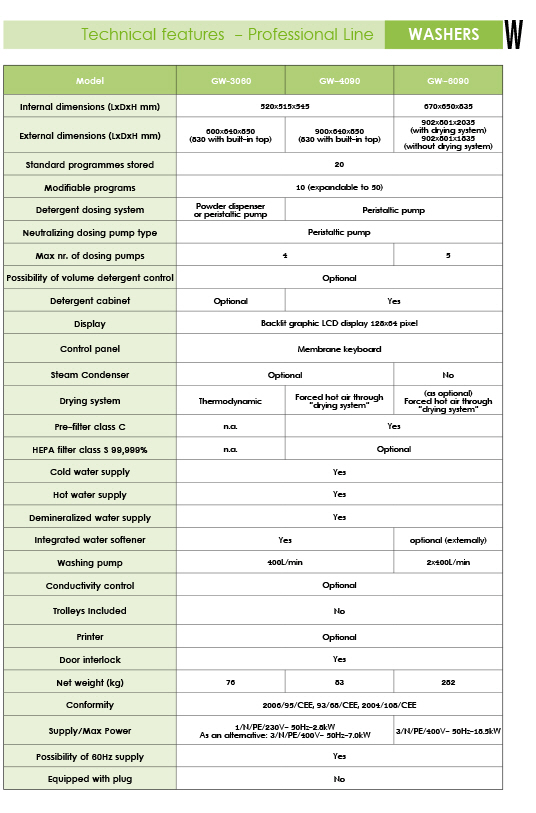

GW3060 is designed

to operate with 1 or 2

levels for treating various types of substance.

*Standard washing chamber 52x51x54cm;

*Possibility of washing, disinfecting and

drying in a forced vaccum

|

|

|

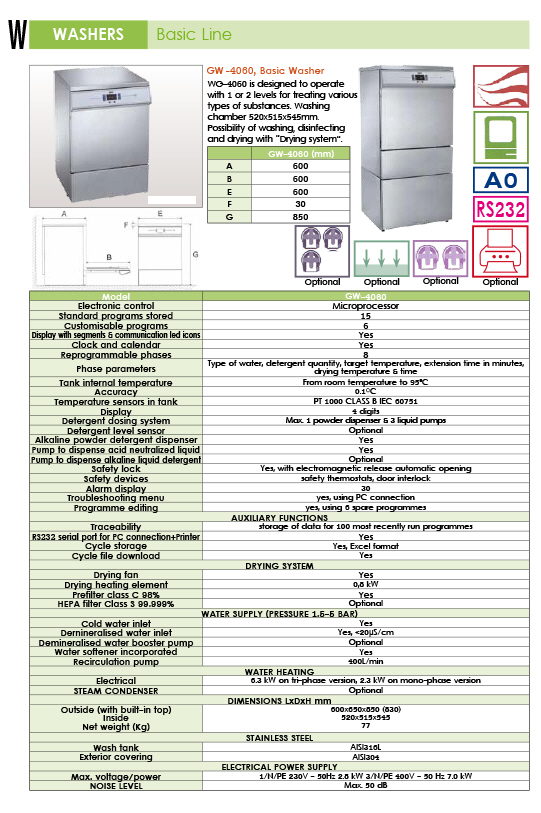

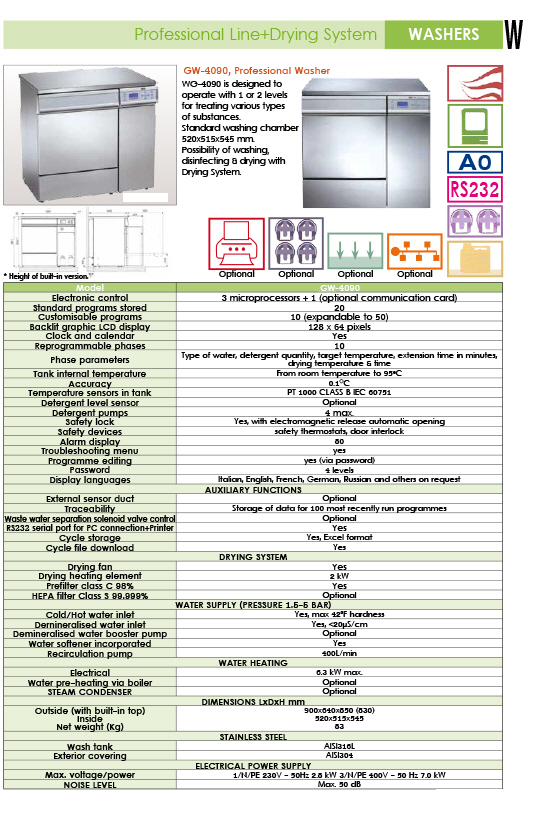

GW4090 is designed

to operate with

1 or 2 levels for treating various types of

substance.

*Standard washing chamber 52x51x54cm;

*Possibility of washing, disinfecting and

drying in a forced vaccum

|

|

|

|

|

|

|

|

| 특징 및 소개내용 |

|

-

|

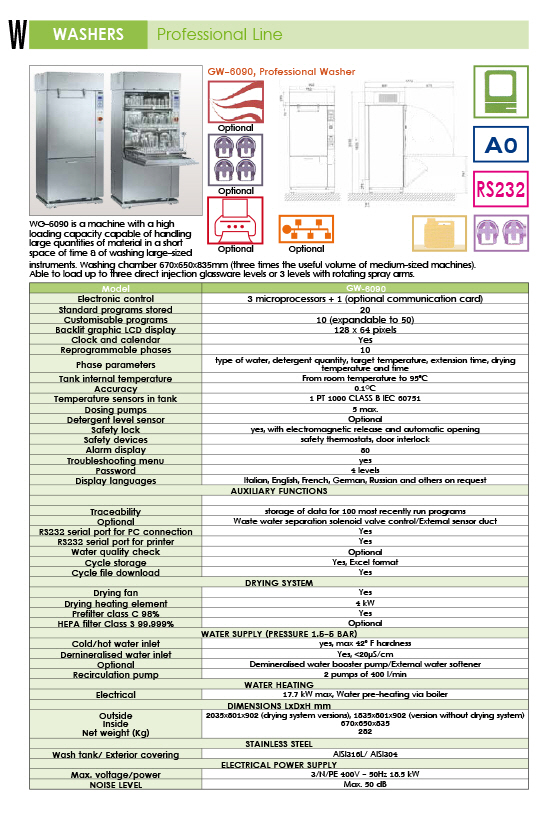

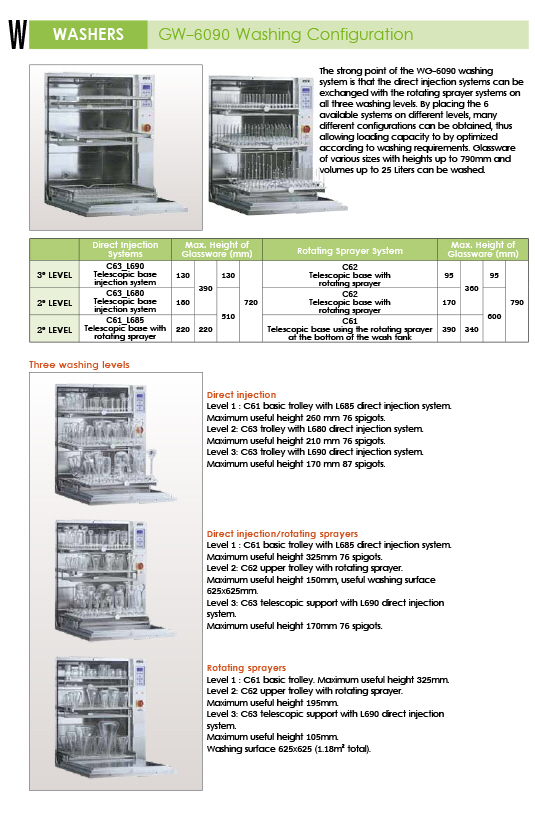

GW 6090 is a machine with a high loading capacity

capable of

handling large quantities of material in

a short space of time and of washing

large-sized

instruments.

• Washing chamber 670×650×835 mm (three

times

the useful volume of medium-sized machines)

• Able to load up to

three direct injection glassware levels or 3 levels with rotating spray arms.

|

|

Accessories

Basic Trolleys

GW6090-GW6090DS Basic Trolleys

GW6090-GW6090DS |

| Product |

|

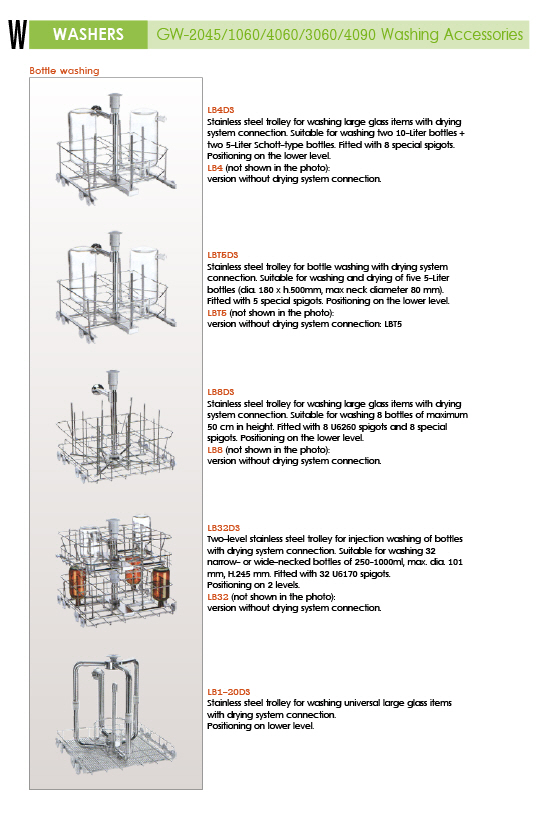

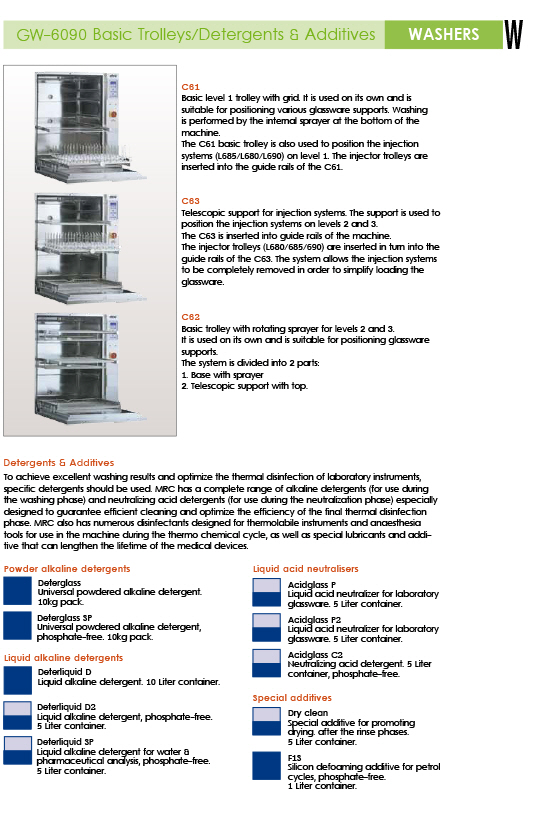

A

Basic trolley for the 1st level equipped with a

grid. It may be used alone and is suitable to position various types of supprots

for glassware. Washing is guaranteed by the bottom rotating spray arm. The C61

trolley may be used to position the injection systems (L685/L680/L690) on the

1st level. The injection trolleys are inserted into the guide rails of the

C61. |

|

B

Telescopic support for injection systems. The

support is used for the positioning of the injecting systems on the 2nd and 3rd

levels. The C63 is inserted into the guide rails of the wash chamber. The

injection systems (L685/L680/L690) may be then inserted into the guide rails of

the C63. The system permits the complete extraction of the injection system in

order to easily load the glassware. |

|

C

Basic trolley with rotating spray arm for the 2nd

and 3rd level. It may be used alone and is suitable to position various types of

supports for glassware. The system is made up of two parts: 1. Base with

rotating spray arm. 2. Telescopic support with

grid. |

|

|

Multispigot

Injection Systems Multispigot

Injection Systems |

|

|

|

Washing

Configurations Washing

Configurations |

THREE WASHING

LEVELS |

| Product |

|

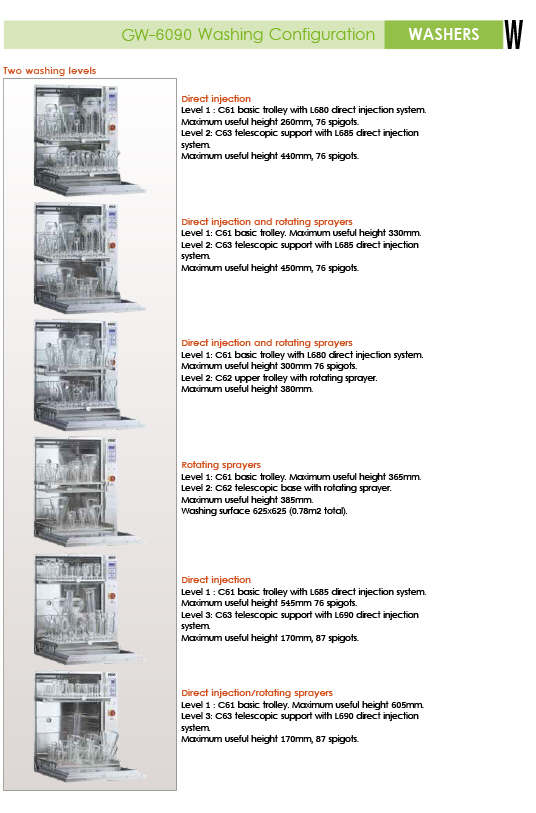

DIRECT INJECTION

1st Level : Basic trolley C61 with

direct injection system L685. Maximum useful height 260 mm, 76 spigots.

2nd

Level : Trolley C63 with direct injection system L680. Maximum useful height 210

mm, 76 spigots.

3rd Level : Trolley C63 with direct injection system L690.

Maximum useful height 170 mm, 87 spigots. |

|

INJECTION / SPRAY ARMS

1st Level : Basic trolley C61

with direct injection system L685. Maximum useful height 300 mm, 76 spigots.

2nd Level : Basic trolley with rotating spray arm C62. Maximum useful height

150 mm, and washing area 625×625 mm.

3rd Level : Trolley C63 with direct

injection system L690. Maximum useful height 170 mm, 87 spigots. |

|

ROTATING SPRAY ARMS

1st Level : Basic trolley C61.

Maximum useful height 365 mm.

2nd Level : Basic trolley with rotating spray

arm C62. Maximum useful height 195 mm.

3rd Level : Basic trolley with

rotating spray arm C62. Maximum useful height 105

mm. |

|

TWO WASHING

LEVELS |

| Product |

|

DIRECT INJECTION

1 st Level : Basic trolley C61 with

direct injection system L680. Maximum useful height 260 mm, 76 spigots.

2 nd

Level : Trolley C63 with direct injection system L685. Maximum useful height 450

mm, 76 spigots. |

|

INJECTION / SPRAY ARMS

1st Level : Basic trolley C61.

Maximum useful height 300 mm.

2 nd Level : Trolley C63 with direct injection

system L685. Maximum useful height 450 mm, 76 spigots. |

|

INJECTION / SPRAY ARMS

1 st Level : Basic trolley C61

with direct injection system L680. Maximum useful height 300 mm, 76 spigots.

2 nd Level : Basic trolley with rotating spray arm C62. Maximum useful

height 380 mm. |

|

ROTATING SPRAY ARMS

1st Level : Basic trolley C61.

Maximum useful height 365 mm.

2 nd Level : Basic trolley with rotating spray

arm C62. Maximum useful height 380 mm. |

|

INJECTION / SPRAY ARMS

1 st Level : Basic trolley C61

with direct injection system L685. Maximum useful height 545 mm.

3 rd Level

: Trolley C63 with direct injection system L690. Maximum useful height 170 mm,

87 spigots. |

|

DIRECT INJECTION

1 st Level : Basic trolley C61.

Maximum useful height 605 mm.

3 rd Level : Trolley C63 with direct injection

system L690. Maximum useful height 170 mm, 87

spigots. |

|

ONE WASHING

LEVELS |

| Product |

|

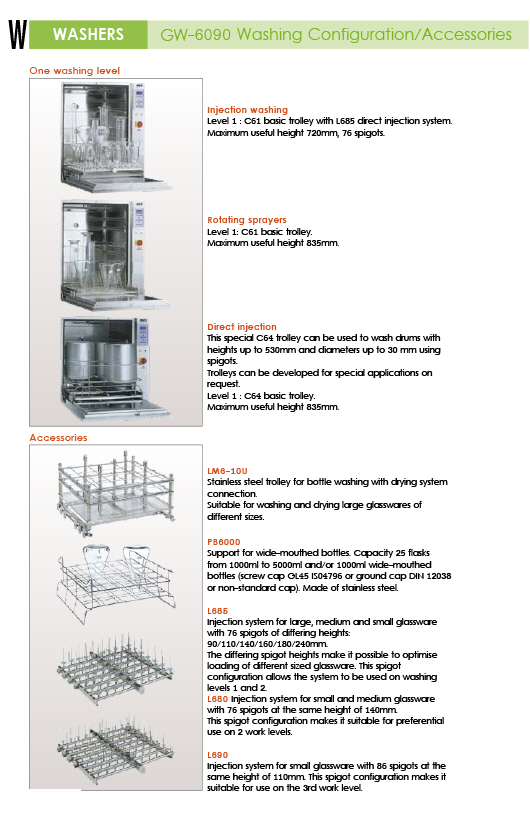

DIRECT INJECTION

1 st Level : Basic trolley C61 with

direct injection system L685. Maximum useful height 720 mm, 76

spigots. |

|

ROTATING SPRAY ARMS

1 st Level : Basic trolley C61.

Maximum useful height 835 mm. |

|

DIRECT INJECTION

Special configuration for washing

large drums.

These special trolleys will be available on request according to

the specifications of the end user.

1 st Level : Basic trolley C64 with

direct injection system. |

|

|

Drying System Accessories

The Accessories used on drying system models

(Quick drying system using forced air) are identified

by the DS suffix showing that the accessories

i

nclude a connection for air injection

through the trolley water circuit

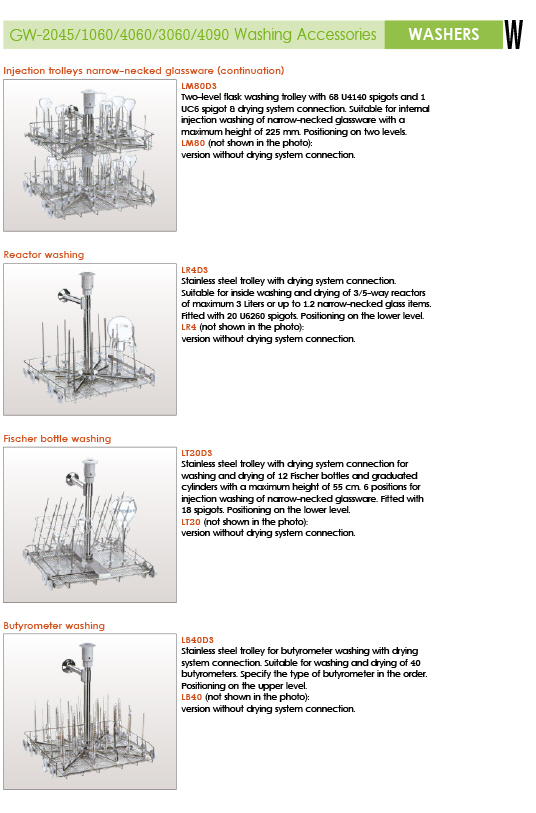

* Flask Washer LM40

* Injection Trolley Nozzles

* LM80 Flask Washer on 2 levels

|

|

|

CS1

Universal top basket with sprayer for holding

the varous glassware supports

* CS2

*PD100S

*SB28(1/2size)

*sb30(1/2size)

*TEst Tube Baskets

|

|

|

|

| |

|

| |

Accessories

|

| |

Injection System I.

Injection System I.

|

Product

|

|

|

1) Flask

Washer LM40

Universal jet trolley for washing narrow-necked

glassware, round bottom flasks and measuring

cyliders. Eight different sizes of interchangeable

nozzles. Maximum capacity 40 items. |

|

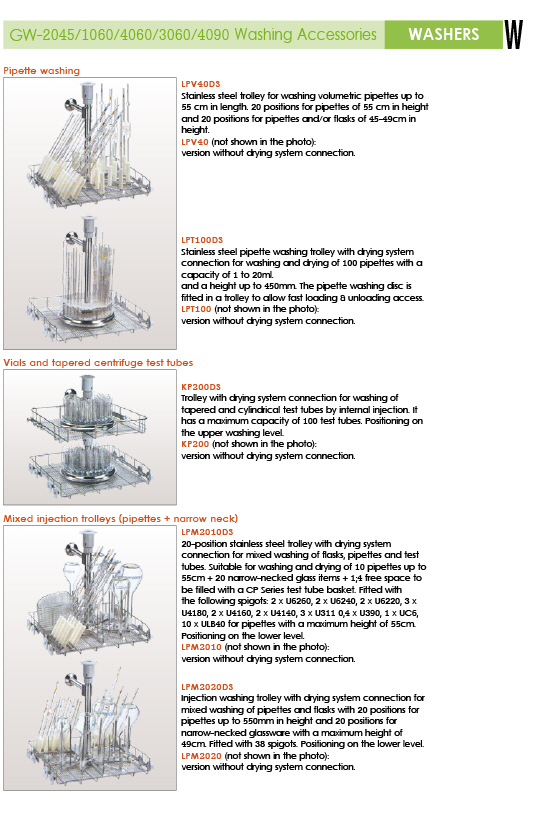

2)

Injection Trolley Nozzles

Available in the following versions : 6% and

12% butyrometer nozzle, pipette nozzle, nozzles

for glassware with the following height measurements

: 90, 110, 140, 160, 180, 220, 240, 260 mm.

|

|

|

3) Drying System Accessories

The Accessories used on drying system models

(Quick drying system using forced air) are

identified by the DS suffix showing that the

accessories include a connection for air injection

through the trolley water circuit. |

|

4) LM80 Flask Washer on 2 levels

Two-level trolley for washing narrow-necked

glassware by internal injection. Capacity

68 items, for glassware with a maximum height

of 225mm. Standard equipment includes 140mm

height nozzles

LM 80DS : two-level flask washer with drying

system connection (not shown) |

|

| |

|

|

|

|

| |

Injection System II.

Injection System II.

|

|

|

|

|

|

|

|

| |

|

| |

Detergents

Detergents

|

| |

• POWDERED ALKALINE DETERGENTS

- DETERGLASS : Universal powdered alkaline detergent,

10kg pack

- DETERGLASS SP : Universal powdered alkaline detergent,

10kg pck, phosphate-free.

• LIQUID ALKALINE DETERGENTS

- DETERLIQUID C : Universal liquid alkaline detergent,

5 litre plastic container.

- DETERLIQUID C1 : Strong Universal liquid alkaline

detergent, 5 litre plastic container.

- DETERLIQUID D : Universal liquid alkaline detergent,

12 litre plastic container.

- DETERLIQUID D1 : Strong Universal liquid alkaline

detergent, 5 litre plastic container.

- DETERLIQUID SP : Strong Universal liquid alkaline

detergent, 5 litre container, phosphate-free

• ACID NEUTRALIZERS

- ACIDGLASS P : neutralizing acid detergent,

6 litre plastic container.

- ACIDGLASS P1 : strong neutralizing acid detergent,

5 litre plastic container.

- ACIDGLASS C : neutralizing acid detergent, 5 litre

container, phosphate-free

- ACIDGLASS C1 : strong neutralizing acid detergent,

5 litre plastic container, phosphate-free

• SPECIAL ADDITIVES

- STREPTOBAT

: Alkaline disinfectant for thermochemical disinfection

cycles at 60℃, 5 litre

plastic contriner, phosphate-free.

- LUB MILK : Protective lubricating emulsion for

stainless steel instruments, 5 litre plastic

container, phosphate-free.

- F1S : Defoaming additive for "petrol"

cycles. Blocks saponification reactions in washing

cycles with addition of caustic soda. 1 litre container.

- K1S : Surfactant ; to be added to the final rinse

in rubber and plastic materials treatment

cycles. 1 litre container.

Ask for the detergent sheets illustrating recommended

uses and methods. |

| |

|

|

| |

| |

|

|

|

Copyright inu trading

Co.,Ltd All right reserved.

고객센터 : (02)802-9719 FAX : (02)802-9720 Contact webmaster@inutra.com

|

|

|

|

|